“Print with Ease – Get Professional Results with Quick Dry Vinyl Sublimation Paper!” – SUBLIMATIONTRANSFERPAPER – Fast Dry Sublimation Transfer Paper Wholesale, A3 Inkjet Sublimation Paper Manufacturer, Made in China

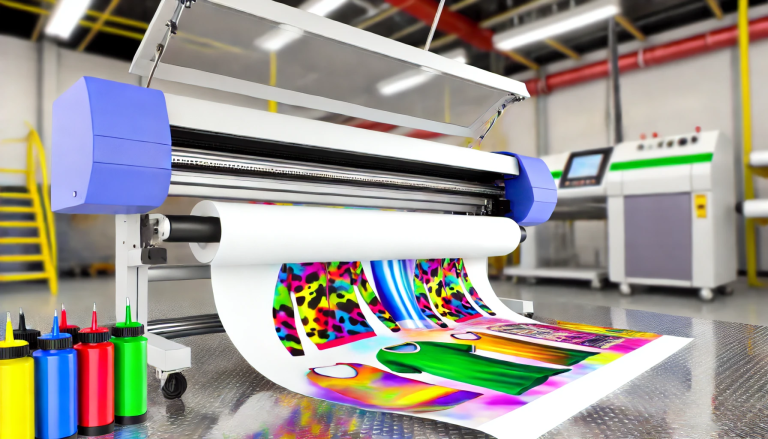

Quick Dry Vinyl Sublimation Paper is designed to reduce ink drying time, boost efficiency, and deliver crisp transfers on vinyl and compatible substrates. Follow this step-by-step guide to maximize its performance and achieve professional results.

1. Preparations: Gather Materials and Prep Design

First, prepare essential tools: Quick Dry Vinyl Sublimation Paper, sublimation inks, a compatible inkjet printer, heat press, heat-resistant tape, and vinyl substrates (ensure they are sublimation-ready with a polyester coating). Create or edit your design in graphic software, mirror it if containing text/directional elements, and adjust the size to fit your vinyl.

2. Print on Quick Dry Vinyl Sublimation Paper

Load the Quick Dry Vinyl Sublimation Paper into the printer with the coated side facing up (check the paper’s indicator if unsure). Print the design using sublimation inks—avoid standard inks as they won’t bond properly. Thanks to its quick-dry feature, the ink will set in 1–3 minutes, eliminating long waiting times and smudges.

3. Position and Secure the Paper

Pre-press the vinyl substrate at 350–375°F (177–190°C) for 5 seconds to remove moisture and wrinkles. Place the printed paper face-down on the vinyl, align it accurately, and secure all edges with heat-resistant tape to prevent shifting during pressing.

4. Heat Press and Peel

Set the heat press to 375–385°F (190–195°C), apply medium-high pressure, and press for 40–50 seconds. Immediately open the press and peel the paper using the hot-peel method (while still warm) for clean, sharp edges. For extra durability, let the vinyl cool completely before handling.

5. Post-Use Tips

Store unused Quick Dry Vinyl Sublimation Paper in a dry, sealed container to avoid moisture absorption. Avoid touching the printed area before pressing, and wash sublimated vinyl items in cold water with mild detergent to preserve the design.