- Industrial Light, Ultra Thin

- Anti-curl, Outstanding lay-flat performance

- Vivid and bright color on fabric

- Superb and quick transfer properties

- Suit for all kinds of polyester and sportswear

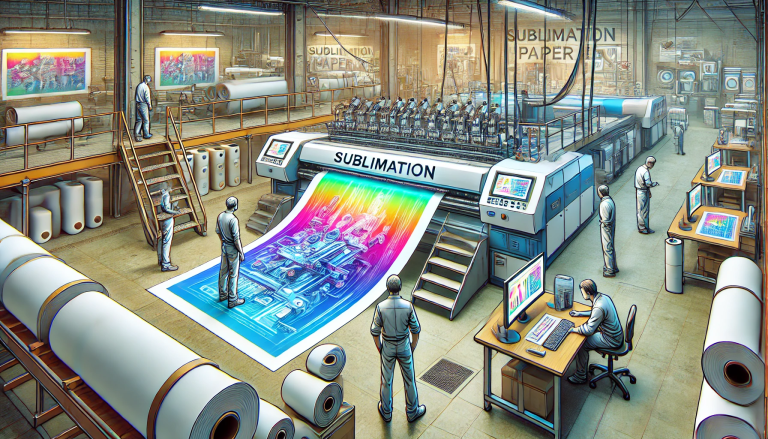

When it comes to sublimation printing, the right materials can make or break your final product. One of the most critical components is heat transfer paper for sublimation printers. This specialized paper plays a pivotal role in ensuring that your designs transfer seamlessly to a wide range of substrates, from polyester fabrics to mugs, phone cases, and more. In this article, we’ll delve into the world of sublimation transfer paper, exploring its features, applications, and how to choose the best option for your projects.

What is Heat Transfer Paper for Sublimation Printers?

Sublimation heat transfer paper is a specially coated paper designed to work with sublimation ink and a sublimation printer. Unlike traditional heat transfer papers, which rely on ink bonding to the surface of the substrate, sublimation transfer paper is used to transfer dye-based sublimation ink onto materials such as polyester or polymer-coated items. During the heat press process, the ink transitions from a solid to a gaseous state, bonding permanently to the substrate without leaving a paper residue.

Key Features of Sublimation Transfer Paper:

- High Ink Absorption: Sublimation transfer paper is engineered to absorb large amounts of sublimation ink, ensuring vibrant and detailed prints.

- Heat-Resistant Coating: The paper’s coating ensures that the ink transfers smoothly and evenly when heated, without sticking or smudging.

- Compatibility: Designed specifically for use with sublimation ink and polyester or polymer-coated substrates.

- Versatility: Available in various sizes, including standard A4, large-format rolls, and cut sheets, to accommodate different project needs.

How Does Sublimation Transfer Paper Work?

Sublimation transfer paper works in conjunction with a sublimation printer and heat press to create high-quality, full-color prints on compatible materials. Here’s a step-by-step overview of the process:

- Design Creation: Create your design using graphic design software such as Adobe Photoshop, Illustrator, or CorelDRAW.

- Printing: Load the sublimation transfer paper into your sublimation printer. Ensure the printer is calibrated and set to the appropriate settings for sublimation ink.

- Heat Press Application: Carefully place the printed paper onto the substrate (e.g., polyester fabric, ceramic mug, or phone case). Set the heat press to the recommended temperature (typically between 380°F and 400°F or 190°C to 205°C) and apply pressure for the specified time (usually 30-60 seconds).

- Transfer: During the heat press process, the sublimation ink transitions from a solid to a gas, bonding permanently to the substrate. The paper peels away cleanly, leaving a vibrant, durable print.

Applications of Sublimation Transfer Paper

Sublimation transfer paper is highly versatile and is used in a wide range of applications across various industries. Some of the most common uses include:

- Custom Apparel:

- T-shirts, hoodies, and sports jerseys made from polyester or polyester blends.

- Sublimation transfer paper allows for full-color, detailed designs that are highly durable and resistant to fading.

- Home Décor:

- Throw pillows, blankets, shower curtains, and tablecloths made from polyester or coated fabrics.

- Sublimation prints add a vibrant and personalized touch to home décor items.

- Promotional Products:

- Mugs, phone cases, keychains, and water bottles with polymer coatings.

- Sublimation transfer paper is ideal for creating branded promotional items with eye-catching designs.

- Sports and Team Gear:

- Custom athletic wear, jerseys, and accessories.

- Sublimation printing ensures that designs remain vibrant and durable, even during intense use.

- Event and Party Supplies:

- Custom banners, tablecloths, and decorations.

- Sublimation transfer paper allows for quick and efficient production of personalized event materials.

Factors to Consider When Choosing Sublimation Transfer Paper

With so many options available, selecting the right sublimation transfer paper can be overwhelming. Here are some key factors to consider:

- Paper Size:

- Choose a paper size that matches your project requirements. Options range from standard A4 sheets to large-format rolls for printing banners and large designs.

- Surface Type:

- Ensure the paper is compatible with the substrate you plan to use. While most sublimation transfer paper works well on polyester and polymer-coated items, some specialized papers are optimized for specific applications (e.g., dark substrates or ceramics).

- Ink Absorption:

- High-quality sublimation transfer paper should absorb ink well, resulting in vibrant and detailed prints. Look for papers with a smooth, high-gloss finish for optimal ink transfer.

- Brand and Reputation:

- Opt for reputable brands known for producing high-quality sublimation transfer paper. Popular brands include Siser, Neenah, and Avery, among others.

- Cost-Effectiveness:

- Consider the cost of the paper in relation to your production volume. While higher-end papers may offer better results, they may not always be necessary for small-scale projects.

- Compatibility with Printers:

- Ensure the paper is compatible with your sublimation printer. Most sublimation transfer paper is designed to work with standard sublimation printers, but it’s always a good idea to check the specifications.

Tips for Using Sublimation Transfer Paper

To get the most out of your sublimation transfer paper, follow these best practices:

- Pre-test Your Materials:

- Conduct test prints to ensure the paper, ink, and substrate work well together. This is especially important when using new materials or experimenting with different designs.

- Calibrate Your Printer:

- Regularly calibrate your sublimation printer to ensure consistent color accuracy and print quality.

- Optimize Heat Press Settings:

- Follow the manufacturer’s guidelines for heat press temperature and time. Incorrect settings can lead to subpar prints or damage to the substrate.

- Use High-Quality Sublimation Ink:

- Pair your sublimation transfer paper with high-quality sublimation ink for the best results. Cheaper inks may compromise the vibrancy and durability of your prints.

- Store Properly:

- Store your sublimation transfer paper in a cool, dry place to prevent moisture absorption, which can affect the ink transfer process.

Common Misconceptions About Sublimation Transfer Paper

- Sublimation Transfer Paper Can Be Used on Any Fabric:

- Sublimation transfer paper is designed for polyester and polymer-coated materials. It will not work on natural fibers like cotton, as the ink cannot bond effectively.

- Any Heat Press Will Do:

- A dedicated heat press with precise temperature and pressure control is essential for successful sublimation printing. Household irons or other alternatives are not suitable.

- Sublimation Transfer Paper is Expensive:

- While sublimation transfer paper may have a higher upfront cost compared to standard transfer paper, its ability to produce vibrant, durable prints makes it a cost-effective choice for businesses and professionals.

Conclusion

Sublimation transfer paper is an indispensable tool for anyone involved in sublimation printing. Its ability to deliver vibrant, full-color designs on a wide range of substrates makes it a favorite among custom apparel makers, home décor enthusiasts, and promotional product creators. By understanding the features, applications, and best practices of sublimation transfer paper, you can unlock the full potential of this versatile material and elevate your printing projects to the next level.

Whether you’re running a small business or a personal hobby, choosing the right sublimation transfer paper and following the proper techniques will ensure your designs shine with exceptional quality and durability. With the right tools and knowledge, the possibilities of sublimation printing are endless.

Sublimation Paper Heat Press, Heat Transfer Paper for Sublimation Printer, Sublimation Transfer Printing Paper, Sublimation Paper for Cups, Large format Sublimation Paper, Dye Sublimation Paper Suppliers, Good Sublimation Paper, Printer Sublimation Paper, Dye Sublimation Transfers, Best Sublimation Paper for T Shirts, Sublimation Paper Brands, Heat Transfer Paper for Sublimation Printer, Cotton Sublimation Transfer Paper, Sublimation Printer Paper for Shirts, Best Sublimation Paper for Phone Cases, Dye Sublimation Paper Suppliers, Heat Transfer Paper for Epson Printer, Dye Sublimation Transfers, Heat Press Paper for Mugs, Sublimation on Cotton Transfer Paper, Epson Ds Multi Use Transfer Paper, Epson Sawgrass Ricoh Inkjet Printer, Heat Transfer Paper for Sublimation Printer, Dye Sublimation Paper Suppliers, Dye Sublimation Transfers,