In the fast-paced world of sublimation printing,Quick Dry Sublimation Paper stands out as a revolutionary innovation, redefining efficiency and print quality for crafters, small businesses, and industrial users alike. Its unique formulation cuts down ink drying time drastically while ensuring vivid, long-lasting transfers—making it a go-to choice for high-volume and time-sensitive projects.

What Makes Quick Dry Sublimation Paper Unique?

Unlike traditional sublimation paper that requires minutes of drying time to avoid smudges, Quick Dry Sublimation Paper features a specialized coated surface that accelerates ink absorption and setting. Typically, the ink dries in 1–3 minutes, eliminating tedious waiting periods and boosting workflow efficiency. This coating also enhances ink retention, ensuring crisp details and vibrant colors that bond seamlessly with polyester-coated substrates like vinyl, fabrics, and hard goods.

Core Advantages for Printing Enthusiasts and Professionals

The benefits of this paper extend beyond quick drying. It minimizes ink bleeding, a common issue with standard papers, especially for intricate designs and large-format prints. For businesses, this translates to reduced waste and consistent, professional results. Additionally, its compatibility with most sublimation inkjet printers makes it accessible, while its durability during heat pressing ensures clean transfers without peeling or fading.

Practical Applications Across Industries

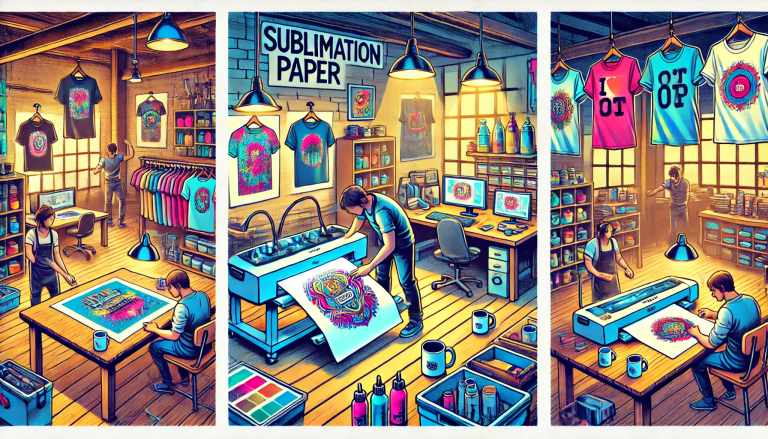

Quick Dry Sublimation Paper shines in diverse scenarios. Crafters use it for custom vinyl decals, personalized apparel, and DIY decor, thanks to its ease of use and smudge-resistant properties. Industrial users rely on it for bulk orders of branded merchandise, team uniforms, and promotional items, as it streamlines production timelines. It also excels in small-batch projects, where quick turnaround and high quality are non-negotiable.

Pro Tips to Maximize Performance

To unlock the full potential of Quick Dry Sublimation Paper, pair it with high-quality sublimation inks and ensure substrates have a polyester coating (the key to successful sublimation bonding). Pre-press substrates to remove moisture, use heat-resistant tape to secure the paper during pressing, and adopt the hot-peel method for clean edges. Store unused paper in a dry, sealed container to preserve its coating and quick-dry capabilities.