http://sublimationtransferpaper.com/product/100gsm-fast-dry-sublimation-paper

Email: adafarrelpj@gmail.com

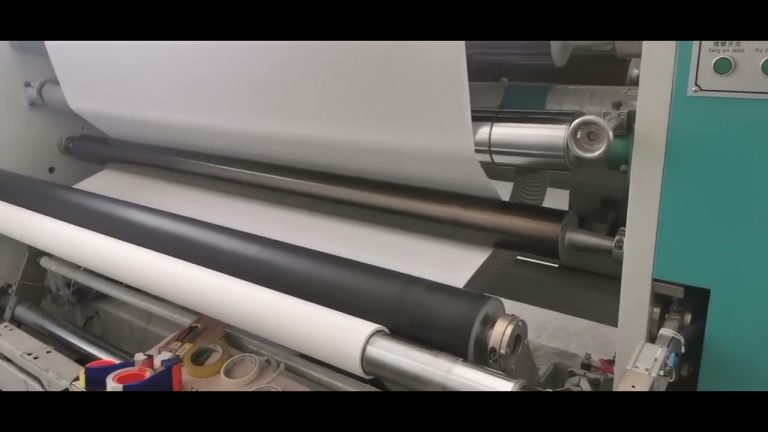

CM PAPER, China Sublimation Transfer Paper, Sublimation Paper Manufacturer, Factory, Supplier, Exporter

Please find more information about our product at follow links:

https://sublimationtransferpaper.com/product/75gsm-fast-dry-sublimation-transfer-paper

https://sublimationtransferpaper.com/product/35gsm-industrial-light-sublimation-transfer-paper

https://sublimationtransferpaper.com/product/100gsm-fast-dry-sublimation-paper

In the world of textile printing, achieving vibrant and long-lasting designs on dark fabrics has always been a challenge. Traditional printing methods often struggle to produce vivid colors on dark backgrounds due to the limitations of ink compatibility and transfer technology. However, the introduction of Dark Transfer Paper Using Sublimation Ink has revolutionized this process, providing a reliable and effective solution for printing on dark fabrics. In this article, we’ll explore how this innovative technology works, its benefits, and its applications in the printing industry.

What is Dark Transfer Paper Using Sublimation Ink?

Dark Transfer Paper Using Sublimation Ink is a specialized product designed to facilitate the transfer of high-quality prints onto dark or black fabrics. Unlike standard sublimation printing, which is primarily suited for light or white polyester fabrics, this method allows for vibrant, colorful designs on darker materials. Here’s how it works:

-

Sublimation Ink: The process uses sublimation ink, which is a water-based dye that turns from a solid to a gas when heated. This ink is specifically formulated to produce vibrant and durable prints on a variety of substrates.

-

Dark Transfer Paper: The paper acts as a middleman between the ink and the fabric. It absorbs the sublimation ink during the printing process and, when heat is applied, releases it onto the dark fabric. The paper is designed with a special coating that enhances ink absorption and transfer efficiency.

-

Heat Pressing: Once the design is printed onto the dark transfer paper, it is placed on the fabric, and heat and pressure are applied using a heat press. The heat causes the ink to sublimate, bonding with the fabric and creating a permanent, vivid print.

Benefits of Using Dark Transfer Paper with Sublimation Ink

-

Vibrant Results on Dark Fabrics One of the most significant advantages of this method is its ability to produce bright, colorful designs on dark or black fabrics. Traditional sublimation ink struggles to show up on darker materials, but dark transfer paper ensures that the colors remain vivid and vibrant.

-

Durability and Wash Resistance The prints created using dark transfer paper and sublimation ink are highly durable and resistant to fading, cracking, or peeling. This makes them ideal for garments and products that undergo frequent washing or wear.

-

Wide Range of Applications Dark transfer paper with sublimation ink can be used on a variety of fabrics, including cotton, polyester, and blends. It is particularly popular for custom apparel, such as t-shirts, hoodies, and sports jerseys.

-

Ease of Use The process is straightforward, requiring only a sublimation printer, dark transfer paper, and a heat press. This makes it accessible for both small businesses and hobbyists.

-

Cost-Effectiveness Compared to other methods for printing on dark fabrics, such as screen printing or direct-to-garment (DTG) printing, dark transfer paper with sublimation ink is more affordable, especially for small-batch production.

How Does Dark Transfer Paper Work on Dark Fabrics?

The process of using dark transfer paper with sublimation ink involves several key steps:

-

Preparation: The dark fabric must be smooth, clean, and free of oils or debris to ensure proper ink adhesion.

-

Design Creation: Using design software like Adobe Photoshop or specialized sublimation design tools, create a high-resolution design for printing.

-

Printing on Dark Transfer Paper: Print the design onto the dark transfer paper using a sublimation printer with sublimation ink.

-

Heat Transfer: Place the printed paper face down on the fabric and use a heat press to apply heat and pressure. The temperature typically ranges between 380°F and 400°F (190°C to 205°C), and the process lasts for about 30–60 seconds.

-

Cooling: Allow the fabric to cool before removing the transfer paper. The result is a vibrant, permanent print on the dark fabric.

Applications of Dark Transfer Paper with Sublimation Ink

-

Custom Apparel Dark transfer paper is widely used for creating personalized t-shirts, hoodies, and jackets. Its ability to produce vibrant prints on dark fabrics makes it a popular choice for fashion brands, event merchandise, and team apparel.

-

Sports and Team Gear Sports teams often use this method to create custom jerseys and gear with bright, eye-catching designs that won’t fade over time.

-

Promotional Products Businesses can use dark transfer paper to create branded merchandise, such as tote bags, hats, and hoodies, for marketing campaigns and giveaways.

-

Home Décor The versatility of this method extends to home décor items, such as throw pillows and tablecloths, allowing for unique, colorful designs on dark fabrics.

-

Art and Photography Artists and photographers can use dark transfer paper to reproduce high-quality prints on canvas or fabric, adding a new dimension to their creative work.

Challenges and Considerations

While dark transfer paper using sublimation ink offers many advantages, there are a few considerations to keep in mind:

- Material Compatibility: Not all fabrics are suitable for this method. Polyester and polyester-cotton blends work best, as the ink bonds well with synthetic fibers.

- Cost of Sublimation Equipment: While the process is generally cost-effective, investing in a sublimation printer and heat press may require an initial financial commitment.

- Temperature Control: Proper heat press settings are crucial for achieving optimal results. Incorrect temperatures can lead to uneven prints or poor adhesion.

Conclusion

Dark Transfer Paper Using Sublimation Ink has transformed the way we approach textile printing on dark fabrics. Its ability to produce vibrant, durable, and customizable prints has made it a game-changer for businesses, artists, and hobbyists alike. By overcoming the limitations of traditional sublimation printing, this technology opens up new possibilities for creating high-quality designs on a wide range of dark materials.

Whether you’re looking to create custom apparel, promotional products, or home décor items, dark transfer paper with sublimation ink offers a reliable and efficient solution. As the demand for personalized, visually striking products continues to grow, this innovative printing method is sure to remain a cornerstone of the textile printing industry.