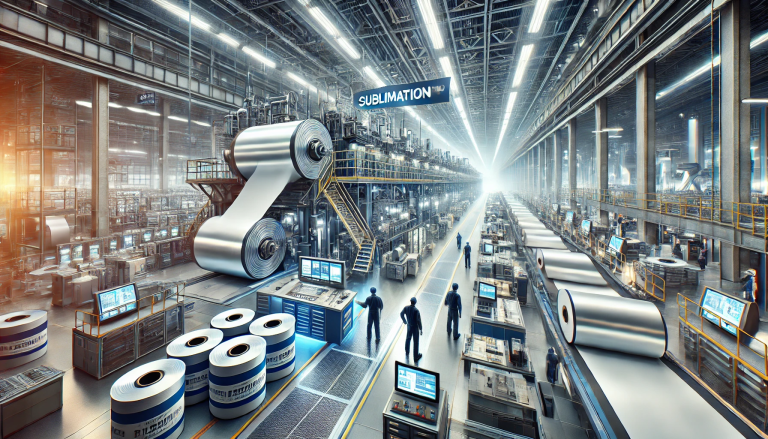

“Transfer Your Designs Quickly and Easily with Will Fast Dry Sublimation Paperwork!” – SUBLIMATIONTRANSFERPAPER – Tacky Sublimation Heat Paper Factory, Sublimation Transfer Paper Roll Manufacturer, Made in China

1. Core Conclusion: Yes, It Works—With Key Compatibility

Fast dry sublimation paper is fully compatible with standard heat transfer processes, designed specifically to integrate seamlessly with heat press technology. Its core function aligns with sublimation’s fundamental principle: using heat (typically 180–200°C/356–392°F) and pressure to convert ink into gas, which bonds with polyester or polymer-coated substrates. The fast-drying feature enhances rather than hinders heat transfer, addressing common inefficiencies of traditional sublimation paper without compromising transfer performance. However, success depends on matching the paper to the right substrates, inks, and heat press settings.

2. How Fast Dry Sublimation Paper Enhances Heat Transfer

The specialized coating of fast dry sublimation paper optimizes heat transfer in two critical ways:

- Ink Locking for Clean Transfers: Its porous, quick-absorbing coating locks in sublimation inks instantly after printing, preventing smudging or ink bleeding during heat press placement—ensuring crisp, precise designs on t-shirts, hoodies, or other apparel.

- Efficient Sublimation Activation: The paper’s thin, heat-conductive structure allows consistent heat penetration, enabling ink to sublimate evenly across the substrate. Unlike standard paper, it eliminates moisture buildup (from slow drying) that can cause bubbling or uneven transfers.

This results in faster workflow (no waiting for drying) and more reliable, high-quality heat transfer outcomes.

3. Key Requirements for Successful Heat Transfer

To maximize results with fast dry sublimation paper in heat transfer, adhere to these essentials:

- Substrate Compatibility: Works best on 100% polyester or high-polyester-blend fabrics (minimum 50% polyester) and polymer-coated rigid items (e.g., mugs, phone cases). It will not bond effectively with pure cotton without a polymer pre-treatment.

- Ink & Printer Match: Must use dye-sublimation inks (not pigment or dye-based inks) with inkjet sublimation printers (Epson, Ricoh, Sawgrass, etc.).

- Heat Press Settings: Follow recommended parameters—180–200°C temperature, 15–30 seconds pressing time, and medium-to-high pressure—to ensure full ink sublimation and adhesion.

4. Common Misconceptions Addressed

- Myth: Fast-drying coating blocks heat transfer.

- Fact: The coating is engineered to be heat-resistant and thin, facilitating rather than obstructing ink-to-substrate bonding.

- Myth: It requires special heat press equipment.

- Fact: It works with standard heat presses (clamshell, swing-away, or auto-open) used for traditional sublimation.

5. Ideal Applications for Heat Transfer Use

Fast dry sublimation paper excels in heat transfer scenarios like:

- Custom apparel (t-shirts, sportswear, hoodies) for on-demand printing or bulk orders.

- Promotional products (branded tote bags, caps) requiring quick turnaround.

- Personalized gifts (polyester fabric keychains, sublimation-ready apparel) where efficiency and quality matter.

In summary, fast dry sublimation paper not only works on heat transfer—it elevates the process by boosting speed, reducing waste, and ensuring consistent, professional results. By following substrate and equipment guidelines, it becomes a valuable tool for businesses and crafters seeking to streamline heat transfer workflows.